High Temperature Lab Ovens

Precision High-Temperature Laboratory Ovens for Demanding Applications

The JIM Engineering High Temperature Lab Oven sets the standard for precision heating in demanding laboratory and industrial environments. Engineered to operate reliably at temperatures up to 500°C (with 600°C models available), these ovens are manufactured to the highest specifications and represent the pinnacle of high-temperature laboratory equipment design.

Aerospace-Grade Performance and Reliability

Widely trusted in the aerospace industry and designed to comply with AMS2750E heat treatment requirements under Nadcap certification, these ovens deliver the exceptional performance and reliability demanded by the most critical applications. Whether you're conducting materials testing, heat treatment processes, or specialized research requiring extreme temperatures, these ovens provide the precision and consistency your work demands.

Advanced Temperature Control Technology

Our sophisticated PID digital controller system manages sheathed heating elements housed below the chamber with exceptional precision. The innovative air circulation design draws air in and premixes it within the base duct before forcing it upwards into the work chamber, achieving typical temperature fluctuation of just ±2°C and stability typically better than ±1°C. This advanced airflow management ensures uniform temperature distribution throughout the chamber, with temperature variation typically within ±5°C.

Superior Insulation and Construction

These ovens feature high-efficiency insulation in both doors and walls, utilizing high-density materials with low thermal mass to minimize heat losses while maintaining cool external surface temperatures. The robust construction includes heavy-duty hinges, catches, and high-temperature seals as standard equipment, ensuring reliable operation even under the most demanding conditions.

Intelligent Safety and Fume Management

Safety is paramount in high-temperature applications. These ovens incorporate calibrated digital temperature overheat safety thermostats and feature a controlled venting system where a small portion of recirculating air is vented from the top of the chamber, allowing any fumes to be safely removed. This design ensures both operator safety and sample integrity during high-temperature processes.

Precision Manufacturing for Critical Applications

Every aspect of these ovens is designed for precision and reliability. The stainless steel chamber construction ensures chemical compatibility and easy cleaning, while the adjustable shelving system accommodates various sample configurations. The powder-coated steel exterior provides durability and an easy-to-clean finish that maintains its appearance even in demanding industrial environments.

Comprehensive Temperature Range Options

Available in both 500°C and 600°C maximum temperature configurations, these ovens provide the flexibility to handle a wide range of high-temperature applications. The 600°C models are specifically designed for continuous use in aerospace and automotive industries, offering the reliability required for critical heat treatment and curing processes.

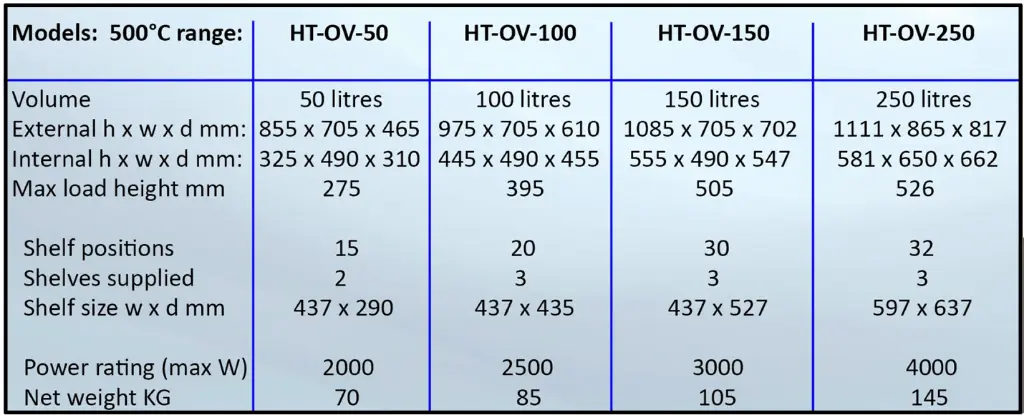

Product Variants

Available in capacities from 50L to 250L in both 500°C and 600°C configurations

Technical Specifications

•Temperature Range: +40°C to 500°C (600°C models available)

•Temperature Stability: ±0.5°C (±1°C typical)

•Temperature Uniformity: ±5°C typical

•Chamber Material: Stainless steel

•Control System: Calibrated digital PID controller

•Safety Features: Digital overheat safety thermostat

•Insulation: High-density, low thermal mass

•Compliance: CE certified, AMS2750E compatible

•Construction: Heavy-duty hinges and catches