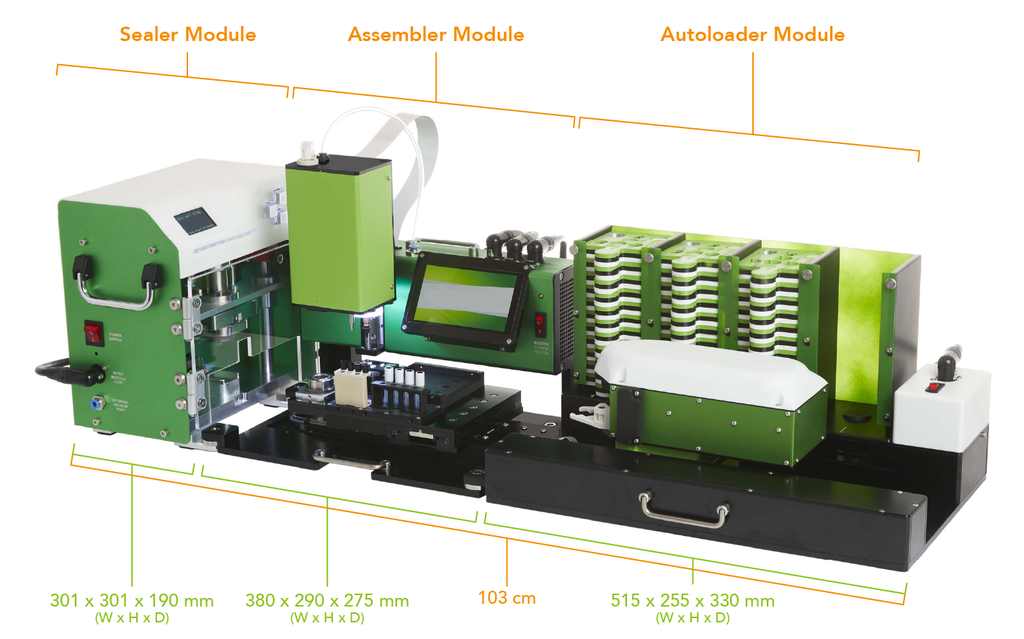

Cell Assembly & Sealing System - Benchtop automated cell production

Autoloader Module

The CASS Autoloader Module holds up to 100 coin or pouch cell trays in a secure holding area ready for transportation to the Assembly Module. Completed cells are returned to the autoloader for storage until the end of the specified build plan. The Autoloader features a highly accurate and flexible robotic arm, which collects the next tray of cell components from the holding area before transporting it with care to the Assembler module for assembly. This module allows you to scale up your automated cell assembly processes with minimal time investment. Filling the Autoloader Module to its 100- tray capacity typically requires a single hour of an entry level technicians time.

Key Features:

- Self-contained, robotic module

- Compatible with both coin and pouch cells

- Pre-prepare up to 100 unique trays ready for assembly

- Make every cell unique, if required, to explore parameter space

- Each cell is contained within its own tray to prevent contamination

- Total setup time of around 1 hour for 100 cells

Assembler Module:

The CASS Assembler Module can transform your prototype coin and pouch cell production capabilities while reducing the overall time and skill levels required to achieve repeatable, high quality test cells. At the Module’s heart is a bespoke pick-and-place unit capable of precisely placing cell components, including curved electrodes, and dispensing exact volumes of electrolytes from the vials and the loading tray provided. As the entire process is computer controlled, each cell can either be identically produced one after another, or you can alter the cell build procedure for each, allowing you to explore electrolyte parameter space and experiment with different materials under a controlled and traceable procedure.

Key features:

- Produce up to 20 cells per hour, with <100 μm misalignment between electrodes

- Reduce cell assembly time by up to 95%

- Produce identical cells every single time, without error

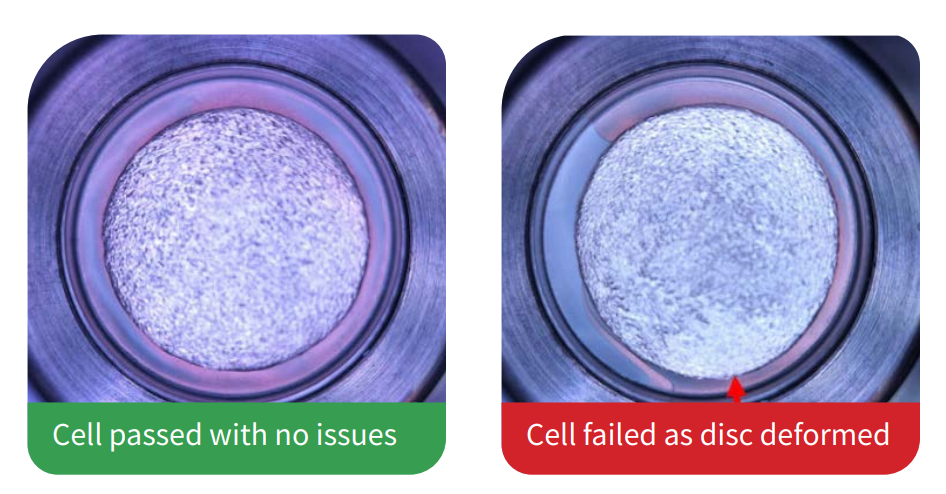

- High-definition cameras log the build of every cell for QC and error tracking

- Large, built-in colour screen guides you through the process

- Lower the skill barrier to cell assembly

- Multiple vial system prevents cross-contamination

Sealer Module

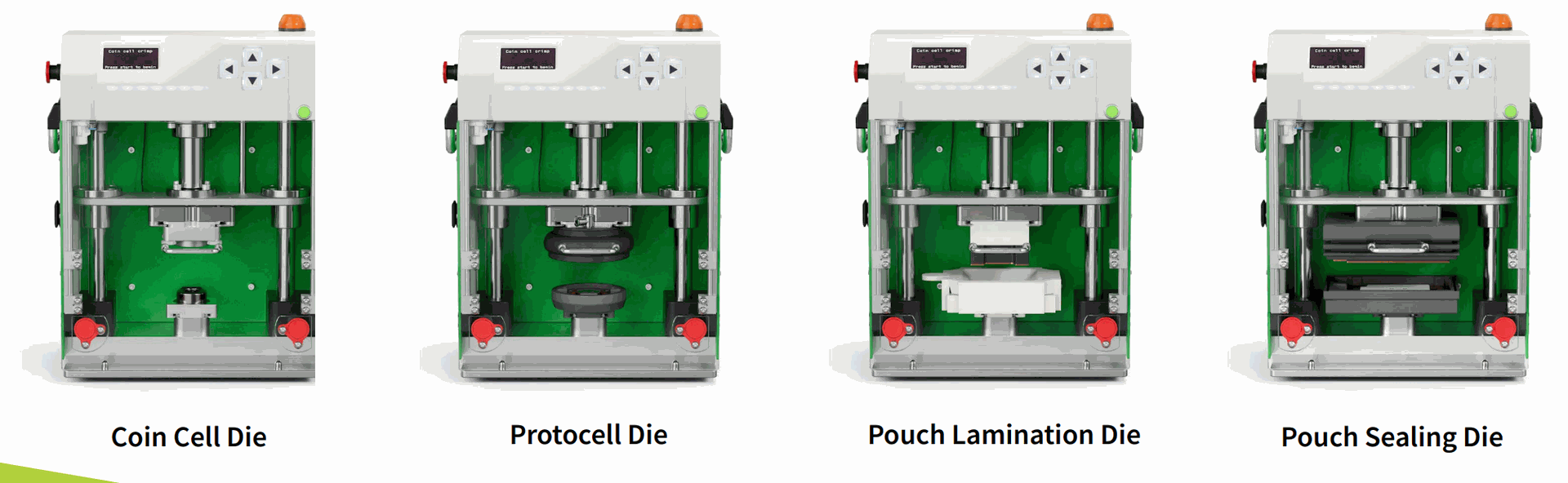

The CASS Sealer Module can be operated in complete isolation from the other Modules, making it the perfect starting point if you are looking for a robust, reliable, and efficient cell and pouch sealing solution with a minimal footprint, with built in pump for pouch cell sealing and no compressed air supply requirement. Once coupled with the Assembler and Autoloader Modules, you can further benefit from a semi or fully automated cell assembly and sealing process. A core design feature of the Module is the interchangeable dies, which allow you to seal coin cells, pouch cells and Protocell batteries and supercapacitors using the unit. A die change requires no specialist tools and typically takes only a matter of minutes to accomplish, allowing rapid technology scale-up from fundamental electrochemical research to applied industry relevant test cells.

Key features:

- High quality coin cell crimper

- Seal pouch cells with up to 40 x 60 mm electrodes

- Swap between coin and pouch cell sealing in 5 minutes

- Seal coin cells, Protocells or pouches with the same unit

- Ultra-compact design, 301mm x 190mm, and 301mm in height

- Built-in display guides you through the sealing process

- Safety guarding and interlock system for protection

- No external compressed air supply required

- Mains powered, comes with KF-40 power feedthrough

Fits easily within standard lab glovebox systems

Measuring a maximum size of 275mm x 570mm (or 330mm x 1,085mm with the Autoloader Module attached), CASS fits easily within all standard lab glovebox systems, each system module can be easily passed through the large antechamber and set up within the glovebox in under two hours. Its compact size allows you to handle all your electrolytes in a safe and secure environment while providing a inert environment for CASS to operate.